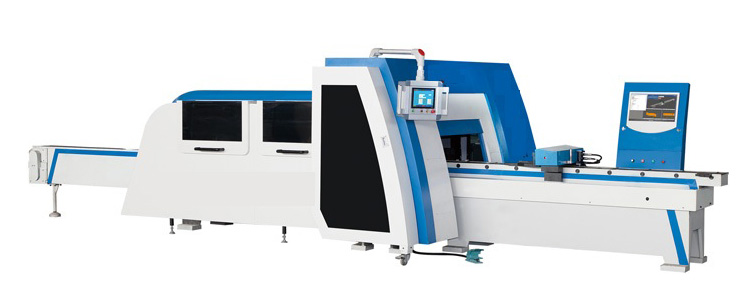

CNC Busbar Punching and Shearing Machine

Basic Info

Model No.: CNC-BP-50

Product Description

Main functions and features:

GJCNC-BP series CNC busbar punching & shearing machine is the computer-controlled equipment of high efficiency and high precision, specially used for busbar processing; Dies of punching, shearing and embossing are placed together in the storeroom of dies; It is capable of executing punching (round, oblong and Other holes), embossing, shearing, slotting, round cornering and other processes; Automatic clamp switching can be achieved without manual intervention for longer busbars. Finished work pieces will be sent out through the conveyor.Such machine series can be used in combination with the CNC busbar bending machine to form an assembly line of busbar processing.

① GJ3D Programming Software:

The software kit of the equipment is the special CAD software (GJ3D) developed by our company, which can be used on line to realize the automation of programing. The software pioneers in applying three dimensional graphics, the state of the art technology, in the industry of busbar processing.Such software is easy to operate,and can display the processed shapes of the copper bar in a visual and three dimensional manner. It is able to calculate the accurate positions of the punched, sheared, and embossed work pieces, and generate the machine code automatically, therefore shortening the time of manual programming and eliminating thepotential errors occurred in manual programming. Such software can demonstrate the entire process of punching, shearing and bending, so as to prevent material waste arisen from the error in manual code entry.

② Main and auxiliary clamps:

For one clamping, the maximum stroke of X Axis is 2000mm, and both the main and auxiliary clamps will operate simultaneously, which will lower the quality requirements on the flatness and bending of the bus bar, thus improving the processing accuracy; during the processing,auto-clamping is obtained to save labor, and to improve the processing efficiency and accuracy;

③ Fast Hauling Belt:

After the processing, the work pieces will be hauled away with the stainless steel hauling belt, so as to improve the efficiency and to protect the work pieces from wearing.

④ Touch Screen:

Human-computer interface is easy to operate and reflects in real time the program execution. It has the function of displaying the alarm message of equipment operation, and allows the easy setting of die parameters and the operation of equipment.

⑤ High-Speed Operation System:

This machine uses high-precision ball screws and linear guides to ensure the high precision and efficiency. Components and elements of national and world famous brands can provide longer service life and guarantee the quality.

⑥ Die Kit:

It has multiple die kit (including dies for shearing, embossing and punching) and adopts integral shearing blade, which is able to cut the busbar at a time, thus improving the processing precision, the section perpendicularity and the processing efficiency; it has special embossing die for producing larger embossing area, thus improving the contactarea of busbar and the processing efficiency; the dies are easy to dismantle and assemble, safe and reliable, and easy to replace, guaranteeing the improvement of productivity under circumstances of frequent replacement of dies. The used die satisfies the requirements on accuracy and performance with the punching time no more than 50000.

Main technical parameter:

| Control Section | ||

| Serial No. | Name | Instruction |

| 1 | Programmable Control | OMRON/Schneider |

| 2 | Sensor | Schneider |

| 3 | Control Button | OMRON |

| 4 | Touch Screen | OMRON |

| 5 | Computer | Lenovo |

| 6 | AC Contactors | ABB |

| 7 | Circuit Breaker | ABB |

| 8 | Servo Motors | YASKAWA(Japan) or Schneider |

| 9 | Servo Drivers | YASKAWA(Japan) or Schneider |

| 10 | Control software and Three-dimensional | Gaoji Busbar Processing System(GJ3D) |

| computer-aided design | ||

| Transmission System | ||

| Serial No. | Name | Illustration |

| 1 | Precision Linear Guide Rail | Taiwan HIWIN |

| 2 | Precision Ball Screw Cylinder | Taiwan HIWIN |

| 3 | Bearing | Japan NSK |

| Hydraulic Section | ||

| Serial No. | Name | Illustration |

| 1 | High Pressure Electromagnetic valve | Italy |

| 2 | High Pressure Tube | Germany Rivaflex |

| 3 | High Pressure Oil Piston Pump | Rexroth |

| Technical parameter | |||

| Description | Unit | Parameter | |

| Press Force | Punching Unit | kN | 500 |

| Shearing Unit | kN | 500 | |

| Embossing Unit | kN | 500 | |

| X Max Speed | m/min | 60 | |

| X Max Stroke | mm | 2000 | |

| Y Max Stroke | mm | 530 | |

| Z Max Stroke | mm | 350 | |

| Stroke of Hit Cylinder | mm | 45 | |

| Max hit speed | HPM | □120 □150 | |

| Tool | Punching Mould | set | □6 □8 |

| Shearing Mould | set | □1 □2 | |

| Embossing Mould | set | □1 | |

| Control Axis |

| □3 □5 | |

| Hole Pitch Accuracy | mm/m | ±0.20 | |

| Max hole punch size | mm | Φ32( Thickness of Copper bar <12mm) | |

| Max embossing area | mm² | 160×60 | |

| Max Allowable sheet dimension(L*W*H) | mm | 6000×200×15 | |

| Total power | kw | 14 | |

| main machine dimension:L*W | mm | 7500X2980 | |

| Total weight | kg | 7600 | |

Our service

--- Inquiry will be replied within 2 hours.

--- All the way tracking service offered from placing order to delivery.

--- We can provide professional guide installation.

--- One year warranty and all round after sale service.

--- Customized design and flow chart are available for our clients.

--- Independent R&D team and strict & scientific management system.

Product Categories : Busbar Punching Machine